Hongjing Electronics (Shenzhen) Co., Ltd

Porque é que a soldadura de placas PCB continua a ser fundamental

While SMT dominates consumer electronics, DIP soldering techniques prove essential for:

- Military hardware (92% mission-critical systems use DIP)

- High-voltage power delivery solutions

- Prototyping requiring manual adjustments

Comparative performance metrics:

| Parameter | DIP | SMD |

|---|---|---|

| Vibration Resistance | +32% | Baseline |

| Thermal Stability | +28% | Baseline |

Essential Tools for Professional PCB Board Soldering

| Equipment | Key Specifications | Usage Tips |

|---|---|---|

| Temperature-controlled Iron | 60W, 200-480°C range | Maintain 350°C±15°C for lead-free alloys |

| Lead-free Solder Wire | Sn99Ag0.3Cu0.7, 0.8mm dia | Apply 3-4mm per joint |

| Flux Pen | RMA-223 certification | Pre-apply to component leads |

9-Step DIP Soldering Protocol

1. Board Preparation

- Clean with 99% isopropyl alcohol

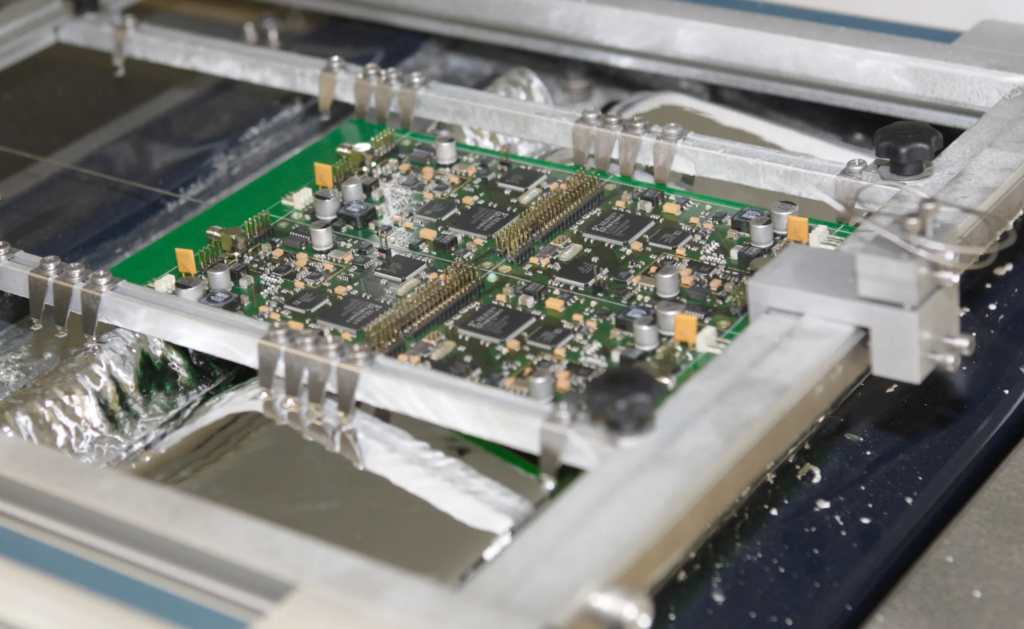

- Secure PCB in ESD-safe vise

2. Component Insertion

- Bend leads at 45° angle

- Ensure full seating against board

Pro Tip: For radial components:

- Insert at 3 o’clock position

- Rotate counterclockwise to 9 o’clock

3. Thermal Preheating

- Set board preheater to 90-110°C

- Critical for:

- Thick copper boards (>3oz)

- Multilayer RF PCBs

4. Soldering Iron Preparation

- Clean tip with brass wool

- Apply thin solder coating

5. Heat Application

- Contact pad+lead junction for 2-3 seconds

6. Solder Feeding

- Feed wire to opposite side of tip

- Allow molten flow to form concave fillet

Avoid: Direct solder-to-tip contact → cold joints

7. Joint Completion

- Remove iron first

- Let solidify naturally

8. Lead Trimming

- Cut within 1.5mm of board surface

9. Final Cleaning

- Remove flux residues with ethanol

- Inspect under 10x magnification

Advanced Techniques for Complex PCB Boards

1. High-Density Assembly

- Implement staggered heating patterns

- Use thermal relief pads

2. Lead-Free Challenges

- Increase tip temperature by 30-50°C

- Consider nitrogen atmosphere systems

Explore automated solutions →

Global Industry Developments

- Miniaturization: <0.5mm pitch components

- AI Inspection: 99.3% defect detection accuracy

- Lead-free Mandates: 86% markets adopted