Hongjing Electronics (Shenzhen) Co., Ltd

FPC Assembly SMT Service manufacturer

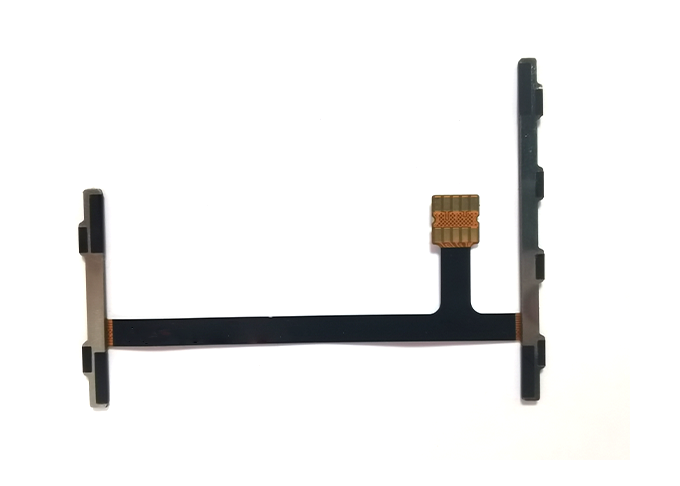

FPC (Flexible Printed Circuit) is a bendable circuit board made of flexible insulating materials (such as polyimide PI or polyester PET), widely used in modern electronic devices, especially in applications requiring lightweight, high-density wiring, or dynamic bending.

1. Core Features of FPC

✅ Flexible and Bendable : Suitable for foldable smartphones, wearables, and other applications requiring repeated bending.

✅ Ultra-Thin Design : Can be as thin as 0.1mm, lighter than traditional PCBs, saving space.

✅ High-Density Wiring : Supports fine traces (line width/spacing can reach below 20μm).

✅ High-Temperature & Chemical Resistance : Some FPCs use special materials for harsh environments like automotive and medical applications.

✅ Stable Signal Transmission : Suitable for high-frequency and high-speed signals (e.g., 5G, mmWave communication).

2. Main Structure of FPC

What also helps is being able to select the ideal manufacturing process. Wave, reflow and selective soldering techniques all have their place. All are available when it comes to identifying the most streamlined workflow for a particular product and production volume. We’re not tied to a specific process.

| COMPONENT | MATERIAL/FUNCTION |

|---|---|

| Substrate | Polyimide (PI), polyester (PET), or other flexible insulating materials |

| Conductive Layer (Copper) | Electrolytic or rolled copper foil (typically 18μm–35μm thick) |

| Coverlay | Protects circuits from oxidation (similar to solder mask) |

| Adhesive | Acrylic or epoxy resin (some high-end FPCs use adhesive-free processes) |

| Stiffener | FR4, stainless steel, etc., to reinforce specific areas (e.g., connector zones) |

3. Classification of FPC

- Single-Layer FPC : Only one conductive layer, simple structure, low cost (e.g., LED strips).

- Double-Layer FPC : Two-sided wiring with vias (e.g., smartphone camera flex cables).

- Multi-Layer FPC (≥4 layers) : For complex circuits, such as high-end foldable phone motherboards.

- Rigid-Flex PCB : Combines FPC and rigid PCB, used in aerospace, military, and other high-end fields.

- Dynamic Bend FPC : Designed for repeated bending (e.g., flip phone hinge cables).

- Static Mount FPC : Requires only one-time bending during installation (e.g., automotive dashboard wiring).

4. FPC Manufacturing Process

1.Material Preparation → 2.Patterning (Exposure/Etching) → 3.Lamination → 4.Drilling/Laser Cutting → 5.Plating (Copper/Gold Deposition) → 6.Surface Finish (OSP/ENIG/HASL) → 7.Testing (AOI/Flying Probe) → 8.Cutting/Forming

5. Typical Applications of FPC

📱 Consumer Electronics : Smartphones (display flex cables, fingerprint sensors), TWS earbuds, foldable devices

🚗 Automotive Electronics : In-car displays, battery management systems (BMS), ADAS sensors

⚕️ Medical Devices : Wearable health monitors, endoscope wiring

🛰 Aerospace : Satellites, drones (lightweight wiring solutions)

🏭 Industrial Control : Robotic joint connections

6. FPC vs. Rigid PCB Comparison

| FEATURE | FPC | RIGID PCB |

|---|---|---|

| Flexibility | ✅ Bendable & foldable | ❌ Not bendable |

| Thickness | Below 0.1mm | Typically ≥0.2mm |

| Weight | Extremely light | Heavier |

| Cost | Higher | Lower |

| Applications | Dynamic bending, tight spaces | Fixed structures, high-power circuits |

7. Future Trends in FPC Technology

🔹 Higher Precision : Trace width/spacing below 10μm (e.g., Micro LED driver circuits).

🔹 New Materials : Transparent FPCs (for flexible displays), stretchable FPCs (bioelectronic skin).

🔹 5G/High-Frequency Applications : Low-loss materials (e.g., LCP) for mmWave requirements.

🔹 Eco-Friendly Processes : Halogen-free, lead-free manufacturing (RoHS compliant).

Conclusion

FPCs, with their flexibility, thinness, and high reliability , have become indispensable in modern electronics. They hold significant potential in foldable devices, automotive electronics, medical applications, and more.

For deeper technical insights (e.g., material selection, impedance control), feel free to inquire further! 😊