홍징 전자(심천) 유한공사

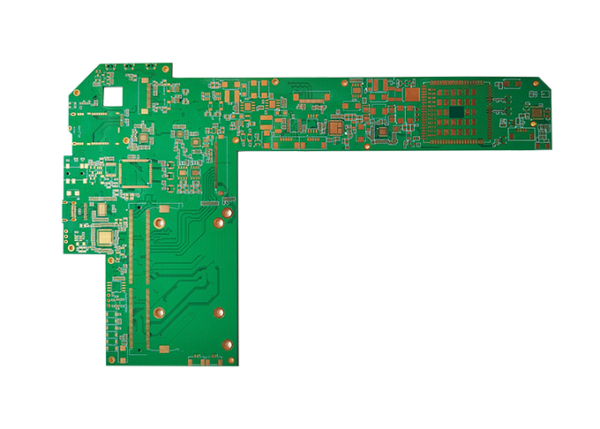

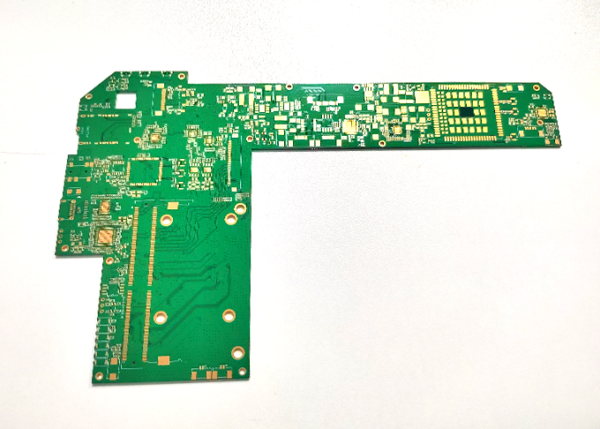

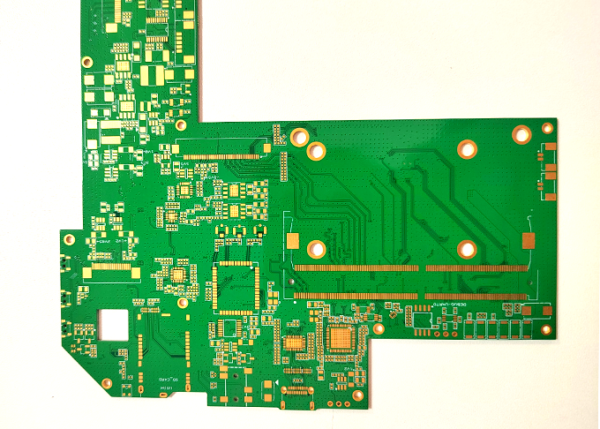

ENIG 8 Layer pcb factory pcb assembly PCB Manufacturing shenzhen printed circuit board 1

Green Printed Circuit Board ENIG 8 Layer shenzhen printed circuit board manufacturers PCB Manufacturing

Brand Name: HJ-PCBA

Model Number: HJ-PCBA-30289

MOQ: 1 pc

Payment Terms: Paypal / , T/T

Supply Ability: 15000-25000square meters per month

Green Printed Circuit Board ENIG 8 Layer shenzhen printed circuit board manufacturers PCB Manufacturing

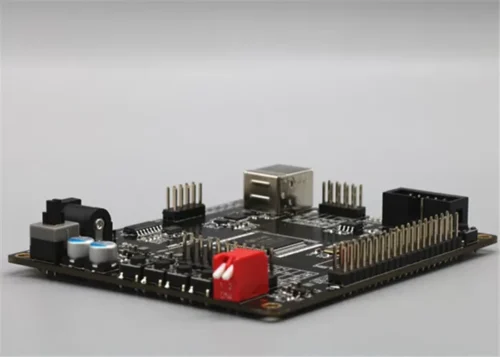

Detailed Specifications

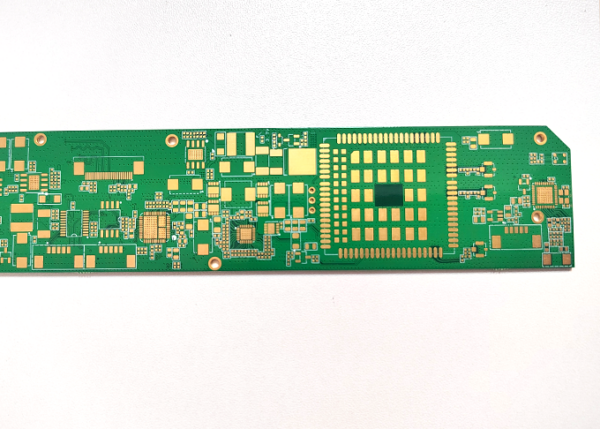

| Material | FR4 |

| Board Thickness | 1.6mm |

| Surface Treatment | ENIG |

| Copper Thickness | 1/1/1/1/1/1/1/1 OZ |

| Soldermask | Green |

| Silkscreen | White |

| The Min Laser Drill Hole | 4 Mill |

| Panel | Breakaway |

Introduction:

The PCB (Printed Circuit Board) is an indispensable core component in electronic devices, used to connect and support electronic components, enabling electrical connections and signal transmission in circuits.

PCB Production:

A PCB (Printed Circuit Board) is a substrate made of insulating materials (such as FR-4), with conductive copper layers formed on its surface through printing or etching processes to create circuit patterns. Electronic components are fixed onto the PCB by soldering and connected electrically through copper traces.

The main components of a PCB include:

– Substrate (typically made of insulating materials, providing mechanical support and electrical insulation).

-Copper Layer (conductive circuits formed on the substrate through etching processes, used for transmitting electrical signals).

– Pad (metal areas used for soldering electronic components).

– Via (used to connect circuits between different layers, classified as through-hole, blind via, and buried via).

– Solder Mask (a protective layer covering the copper layer to prevent short circuits and oxidation, usually in colors such as green, blue, white, black, or red).

– Silkscreen (text or symbols printed on the PCB surface to identify component locations, part numbers, and other information).

SMT Production:

SMT (Surface Mount Technology) is an advanced manufacturing process that directly mounts electronic components onto the surface of a printed circuit board (PCB). Compared to traditional through-hole technology (THT), SMT offers higher production efficiency, smaller component sizes, and better electrical performance. SMT production is widely used in consumer electronics, communication devices, automotive electronics, medical equipment, and more.

The main processes of SMT production include:

1. Solder Paste Printing: Applying solder paste onto the PCB pads through a stencil.

2. Component Placement: Using a pick-and-place machine to accurately mount electronic components onto the PCB.

3. Reflow Soldering: Heating in a reflow oven to melt the solder paste and form reliable electrical connections.

4. Inspection and Testing: Using AOI (Automated Optical Inspection), X-ray inspection, and functional testing equipment to ensure soldering quality and circuit functionality.

The advantages of SMT production include:

– High Density: Supports miniaturization and highly integrated electronic designs.

– High Efficiency: High level of automation, suitable for mass production.

– High Reliability: Stable soldering quality and excellent electrical performance.

DIP Production:

DIP (Dual In-line Package) is a traditional form of electronic component packaging where the pins are inserted through holes in a printed circuit board (PCB) and soldered in place. DIP production is widely used in applications requiring high reliability and ease of manual soldering, such as industrial control and power equipment.

The main processes of DIP production include: applying back adhesive (to prevent tin plating in unwanted areas), component insertion, wave soldering, cleaning, and inspection and testing.

The advantages of DIP production are: high reliability, ease of manual soldering, and low cost.

DIP production is a classic electronics manufacturing process. Although it has been gradually replaced by SMT in modern high-density electronic designs, it remains important in applications requiring high reliability, manual soldering, and low cost.

| Brand Name | HJ-PCBA |

|---|---|

| Model Number | HJ-PCBA-30289 |

| MOQ | 1 pc |

| Payment Terms | Paypal / , T/T |

| Supply Ability | 15000-25000square meters per month |

상품평

아직 상품평이 없습니다.